Areas of Application and Examples

Rapid Prototyping for Rapid Production-Ready Products

3D printing can significantly shorten the development time from the idea to the market-ready product (time-to-market). The first prototypes are designed in CAD programs and can be printed immediately. Weaknesses can be discovered, and improvements can be transferred directly to the model. This reduces waiting times in the development process and enables a smoother workflow.

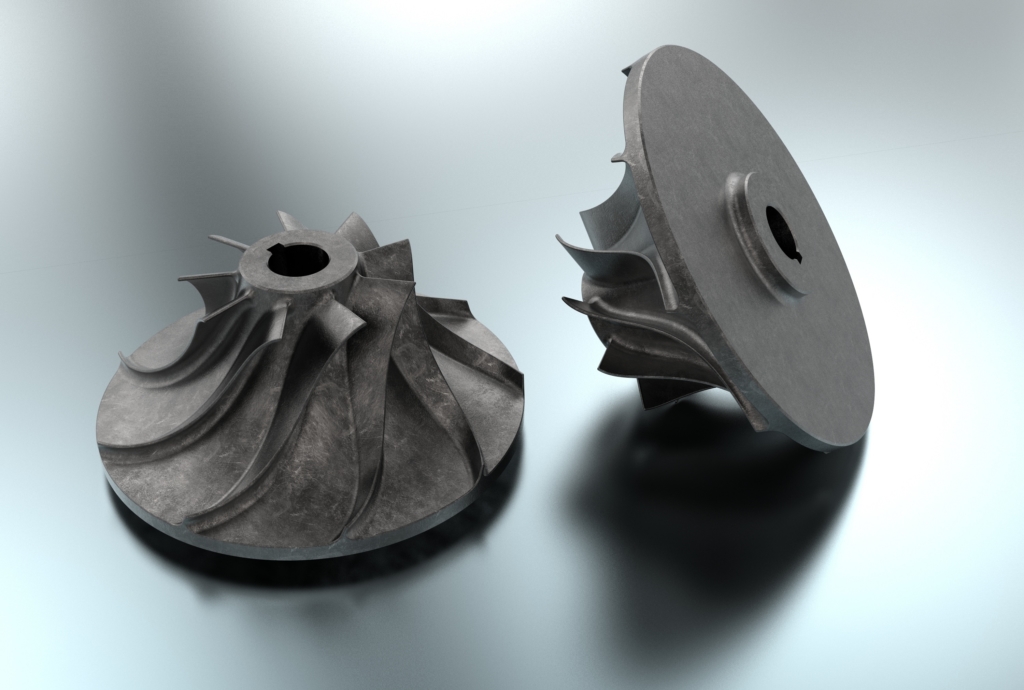

Rapid Tooling

Using 3D printing technology, complex tools and master models for injection molding or other tool-related processes are created directly in one production step. Here, various metals, such as tool steel, are used. Additive manufacturing allows the integration of functions such as cooling channels.

Medicine and science

For medicine, 3D printing offers revolutionary possibilities, for example, in implantology or in the manufacture of prostheses. Medical ceramics are already used today to produce several individual dental implants in one step, which significantly reduces the per-piece production costs.

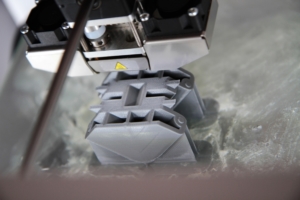

Individual (small) serial production

3D printing is an interesting technology for industry 4.0 because the production process allows customized serial production of one or more objects at the same time. The procedure is always the same – only the CAD model needs to be adapted. This enables the consideration of specific customer requirements without additional production costs.